- Home

- Products

- Technical Resources

- Testing & Support

- About MOLYKOTE®

- Contact Us

Your IFF account is now accessed at ChemPoint.com.

You will use the same username and password to log in.

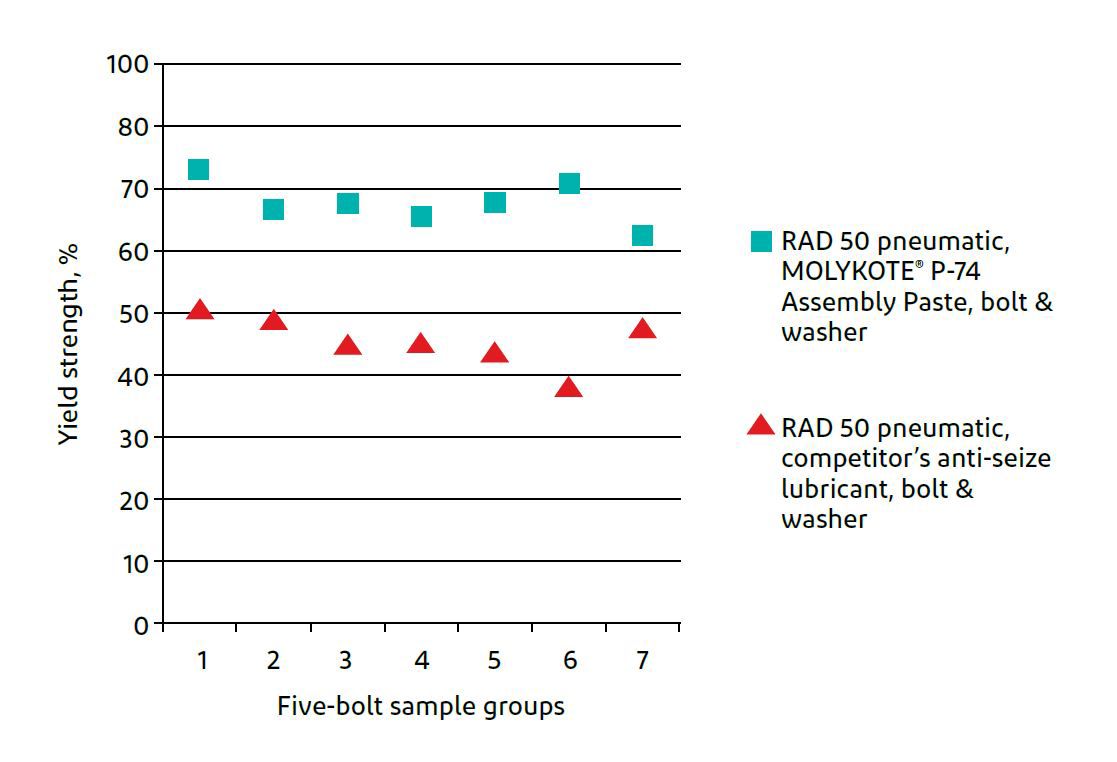

To meet high expectations, Relining Minerals and MPS researched many different lubricants; MOLYKOTE® P-74 Assembly Paste was one such lubricant. MOLYKOTE® P-74 Assembly Paste was primarily chosen for its low coefficient of friction. It was compared to other leading lubricant solutions.

During bolt-tensioning trials, MPS brought in a pulp lifter liner configured with M48 liner bolts from a 36-foot SAG mill. The test jig was used to calibrate the actual torque/bolt load and, through proper lubrication, get it closer to the calculated torque/bolt loads to reduce the variation in the bolt loads achieved.

|

Bolted connections

|

Exhaust bolts

|

|

Sliding contact bearings

|

Spark plug threads

|

|

Linear sliding guides

|

Flanges and flange seals

|

|

Splined shafts

|

Door hinges

|

|

Press-fit joints

|

Brake mechanisms

|

Your document download should begin shortly. If not then please click the Download button below to view your document.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collected is solely used to support ChemPoint's customer service communications. Read our Privacy Notice.

Thank you for your inquiry and interest! We will respond to you shortly.

Thank you for your inquiry and interest! We will respond to you shortly.

Thank you for your inquiry and interest! We will respond to you shortly.